|

PARTNER no. 2/11 |  |

Pav. 8 Stand 02 |

|

| Company Name | FARM NEW BRASS SRL Via Madre Teresa di Calcutta n. 2/4 – 10073 Ciriè (Turin) Italy Phone: +39 011 9222344 – Fax: +39 011 9215700 Website: www.farmbrass.com Mail: info@farmbrass.com |

|||

| Commodity Sector | 31.00 – machines, systems and equipment for casting | |||

| Company Profile | Born in 1977, FARM Brass company was able to quickly establish itself in the field of non-ferrous metals heating, revolutionizing the philosophy of heating/forging in automatic, offering patented gas furnaces suitable to feed the new range of press machines with continuous operation. In more than 35 years of activity we have installed over 1500 systems, divided by thrust furnaces, chain furnaces, belt furnaces and special.

Among the patents characterizing our production we point out the one for lining up the parts, for total emptying of billets inside the heating chamber and, last but not least, the one for self-supporting meshes in our chain furnaces. The company philosophy, professionalism of our technicians, along with high technological content of proposed solutions has enabled us to expand the application field over the years. The continuous research and studies carried out in collaboration with the best Italian universities allowed us to manufacture heating systems where words “energy saving” have become more and more important; the result is the optimal dosing and recycling of heating produced during combustion. Recently inaugurated the new headquarters, now FARM Brass has available an area of 11.000 m2 of which 5.500 are covered. |

|||

| Processing Step | ROD HEATING AND CUTTING | |||

| Processing Step description |

|

|||

| Particularly interesting processings | The furnace is equipped with a loader for bars having a length of 3 mt and allows the cutting of the hot billet granting a minimum waste of material. | |||

| Machines and/or equipment and/or employed materials | Drive HIP 601 Esautomotion

CNC S640.551 (dislay 15″,321+320,CAN) Module for remote assistance SE1149 Secomea Infrared optical pyrometer model DGF40N Dias E- motors series Esautomotion Combustion components Krom Schroder |

|||

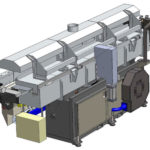

| Characteristics or innovative applications (machines, equipment, employed materials) | This furnace has been designed for the brass bars heating with integrated cutting system.

The indirect heating system grants a gradual heating of all the bar and the cutting system without burr makes easier the deformation of the heated piece inside the mould. All the six main movements are managed by a CN by means of brushless motors and other two movements of lower use are controlled by means of linear transducers. The management software of the machine permits, during the functioning cycle, the fine adjustment of the billet weight by means of some correction parameters. |

|||

| Application Fields | Fittings, locks | |||

| Gallery |

|

|||