|

PARTNER no. 6/11 |  |

Pav. 8 Stand 06 |

| Company Name | COGEIM EUROPE SRL Via Villapia n. 9/11 – 20010 Casorezzo (Milano) Italy Phone: +39 02 9032261- Fax: +39 02 90296850 Website: www.cogeim.it/en/ Mail: info@cogeim.it |

||

| Commodity Sectors | 79.00 -machines and equipment the treatment and finishing surfaces 82.00 – machines for cleaning metals |

||

| Company Profile | COGEIM EUROPE has been designing and manufacturing shot blasting, shot peening and sandblasting installations for more than 40 years. Thanks to its experience, the technical expertise of its engineers and the continouos technological innovation, Cogeim manufactures machineries which stand out for their very high quality, fulfilling the requirements of its customers. Cogeim Europe is certified according to regulation UNI EN ISO 9001:2000. | ||

| Processing step | SANDBLASTING | ||

| Processing step description | Feeding of work pieces After the cooling process, the work pieces leave the cooling tunnel and are conveyed, via a rubber belt conveyor, to a shot-blasting machine for the blasting process. Shot-blasting After the closing of the loading / unloading door, the movement of the rubber mat of the shot-blasting machine start the tumbling of the work pieces. As the abrasive supply valve opens, the turbine throws the abrasive against the work pieces at very high-speed (more than 80m/s), performing the surface cleaning treatment. Offloading of the machine At the end of the selected blasting time, the blasted parts are offloaded onto a rubber conveyor belt, which conveys them to the robotic transfer loading device. |

||

| Particularly interesting processings | Loading of the work pieces into the shot-blasting machine through mobile conveyor, capable of preventing the dents on the parts treated in bulk. | ||

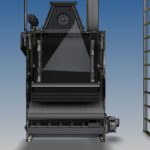

| Machines and/or equipment and/or employed materials | Rubber belt conveyor shot-blasting machine, type COGEIM TG 1, complete with FC 4 – ATEX cartridges dust collector. | ||

| General data sheet (machines, equipment, employed materials) | See the Section “Gallery”, or visit the following website: http://www.cogeim.it/en/cp43/shot-blasting-machine-mod.-tg-1/ | ||

| Characteristics or innovative applications (machines, equipment, employed materials) |

|

||

| Application fields | The TG type rubber belt shot blasting machines are used in forging, foundry, metal work, aluminum industry, automotive industry, etc.

Typical applications include:

|

||

| Gallery |

|

||

| Video | |||