|

Company Name

|

CEEVER SRL

Via Battisti, 2 – 20090 Settala (Milan) Italy |

Stand ..

|

| Company sectors | 05.00 – work piece and tool handling

36.00 – machines for deburring and chamfering 79.00 – machines and equipment for surface treatment and finishing 80.00 – machines and equipment for galvanic treatments 81.00 – machines and equipment for heat treatments 100.00 – systems and equipment |

||

| Company Profile | Born in January 1959, Ceever deals in the production of plants for chemical-physical surface treatment.

The production is very large: from sandblasting machines to tunnels of washing, moving to plants of phosphating, burnishing, pickling, etc. All systems are available in 2 versions, standard and special, designed to satisfy each specific requirement of the customers. Ceever assures its customers technical supports throughout the life cycle of the machine, thanks to its specialized technicians, and, moreover, ensures a large availability of spare parts. It operates in the following sectors: automotive, aerospace, mechanical machining, heat treatment, oil & gas, white goods, medical, rail, marine, industrial machines, arms and energy. |

||

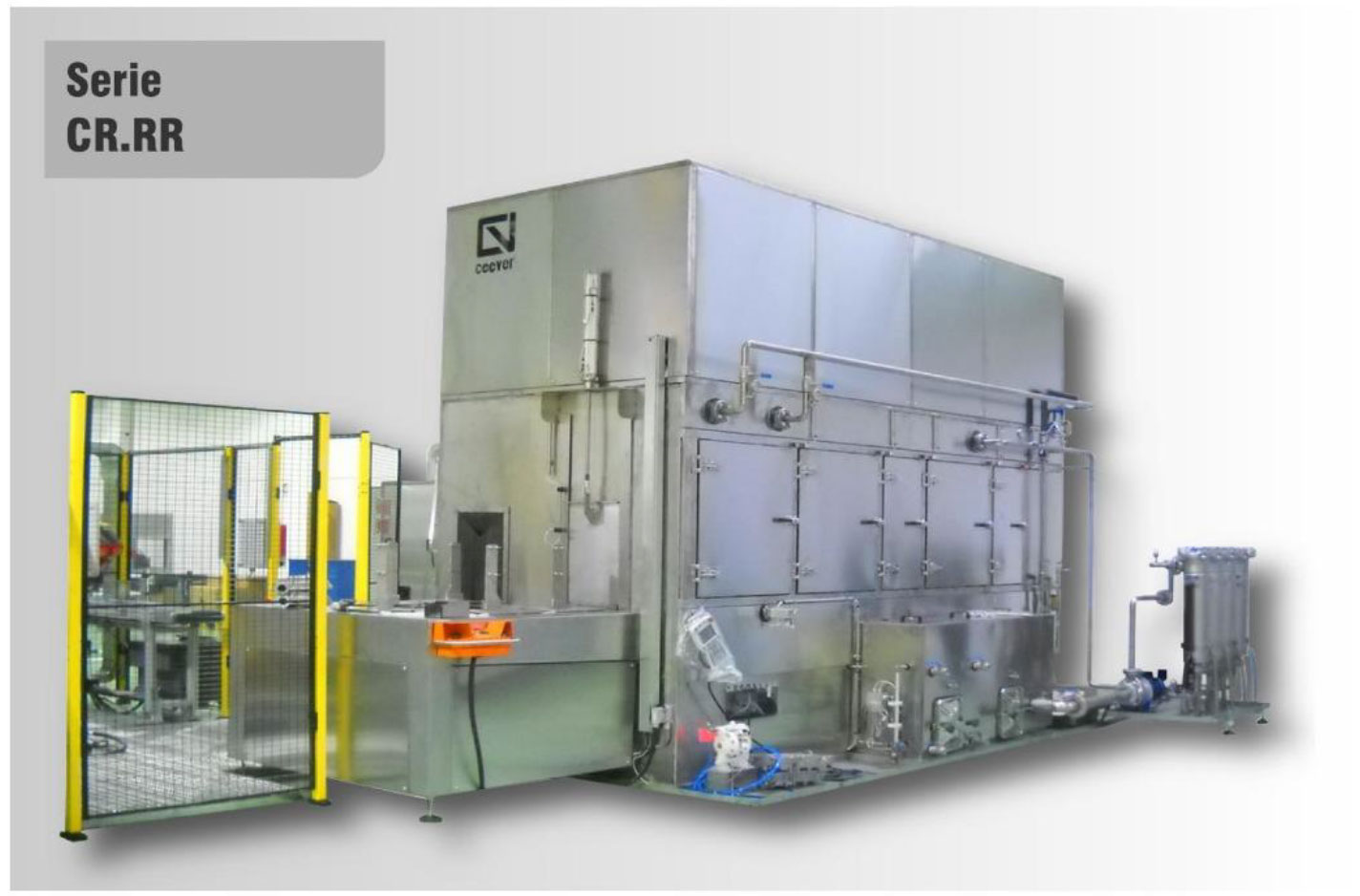

| Exhibited Products | High-precision washing and deburring – CR.RR Tunnel Series System

This plant is characterized by the use of robots both for piece loading/unloading and for deburring; it is rather suitable for the companies needing a high washing level even regarding to pieces with particularly complex shapes, which have spots that are not so easy to reach. (as, for example, cam covers in car engines). The system is composed of an anthropomorphic robot with one or more spray nozzles fixed to the wrist. The system works in a high pressure circuit and is particularly interesting for deburring processes for the removal of precarious burrs generated by mechanical processing. This high pressure robotic system for washing and deburring is particularly versatile because it allows to treat parts with different shapes by means of changes to the management software of the robot. |

||

| Gallery |

|

||

| Video | |||